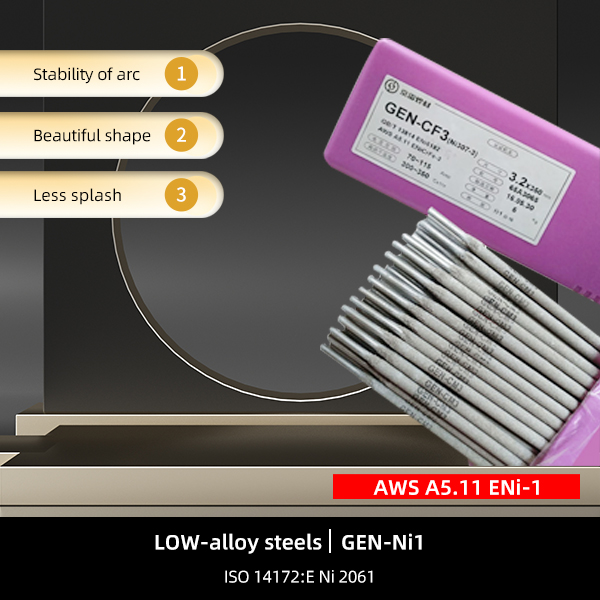

Nickel alloys Manual electrode ENi-1 weld fabrication makings

COMPONET CHEMIKA:

| FITIAVANA (wt%) | C | Mn | Si | Ni | Fe | Ti | Cu | P | S |

| GB/T RATSY | 0.10 | 0.75 | 1.20 | ≥92 | 0.70 | 1.0-4.0 | 0.20 | 0.02 | 0.015 |

| AWS RULES | 0.10 | 0.75 | 1.25 | ≥92 | 0.75 | 1.0-4.0 | 0.25 | 0.03 | 0.02 |

| VALUE OHATRA | 0.046 | 0.06 | 0.82 | 95.5 | 0.12 | 2.7 | 0.01 | 0.007 | 0.001 |

FANANANA MEKANIKA:

| NY FANANANA | HERINANDRO (MPa) | HERIN'NY FANITATRA (MPa) | IMPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RATSY | 200 | 410 | - | 18 | ||||

| AWS RULES | - | 410 | - | 20 | ||||

| VALUE OHATRA | 310 | 435 | - | 29 | ||||

PARAMETER WELD RECOMMENDED:

| SPECIFICATIONS DIAMETERS (mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||||

| HERINATRATRA (Amp) | H/W | 65-95 | 70-115 | 95-145 | ||||||

Titanium-kalsioma tanana electrode, nominal composition (isan-jato amin'ny lanjany) dia 95Ni-2.5Ti.

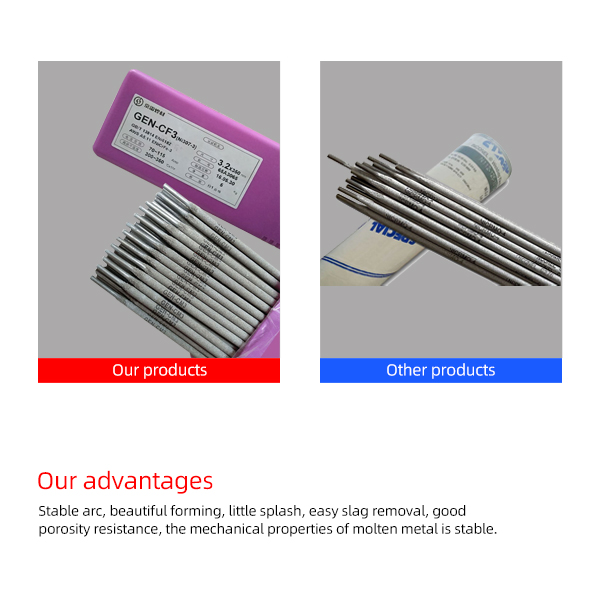

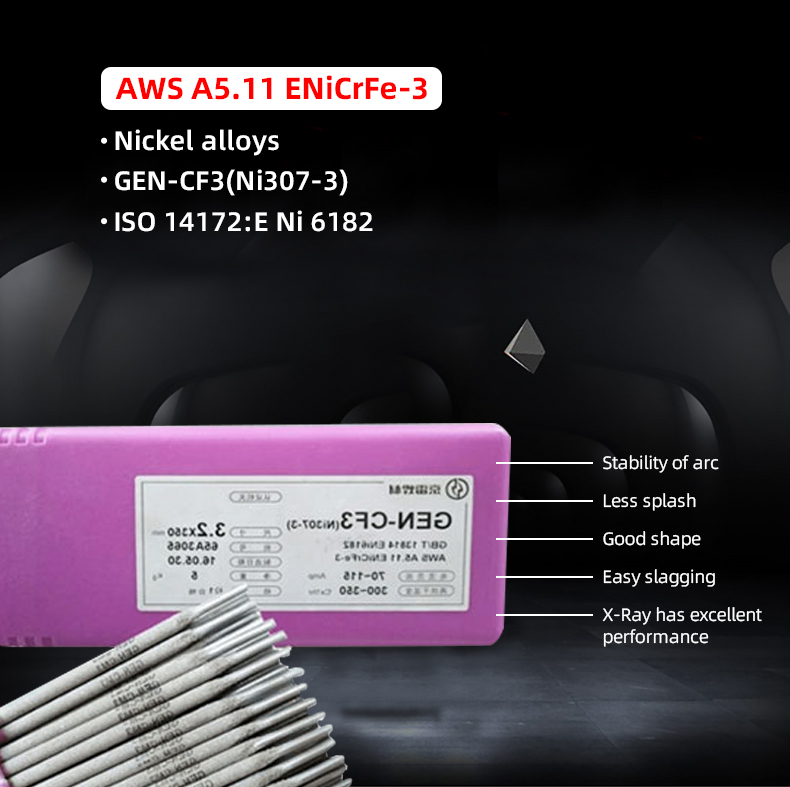

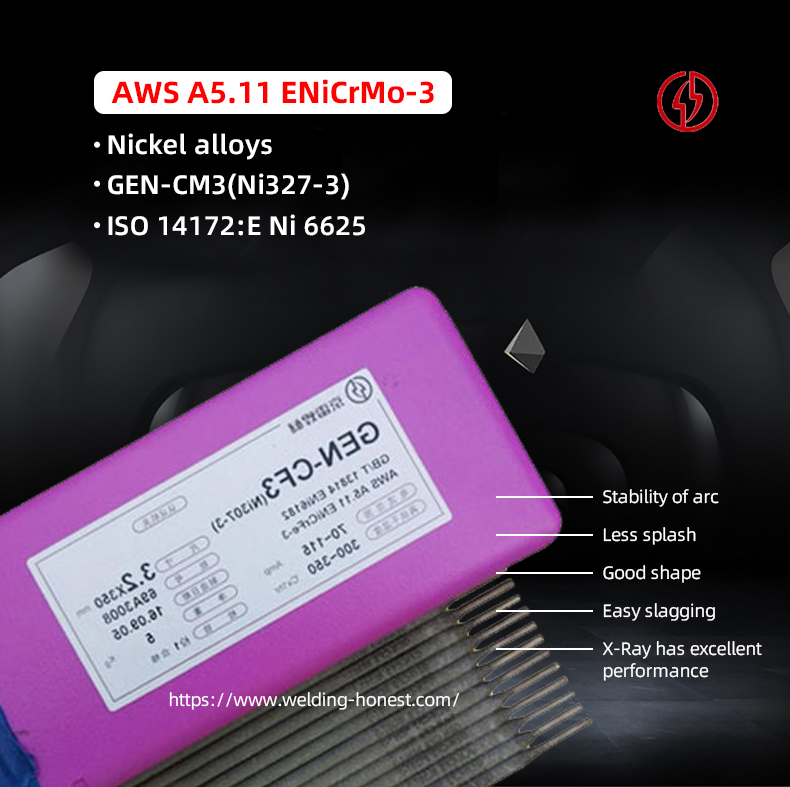

Arc stable, endrika tsara tarehy, splash kely, fanesorana slag mora, fanoherana porosity tsara.

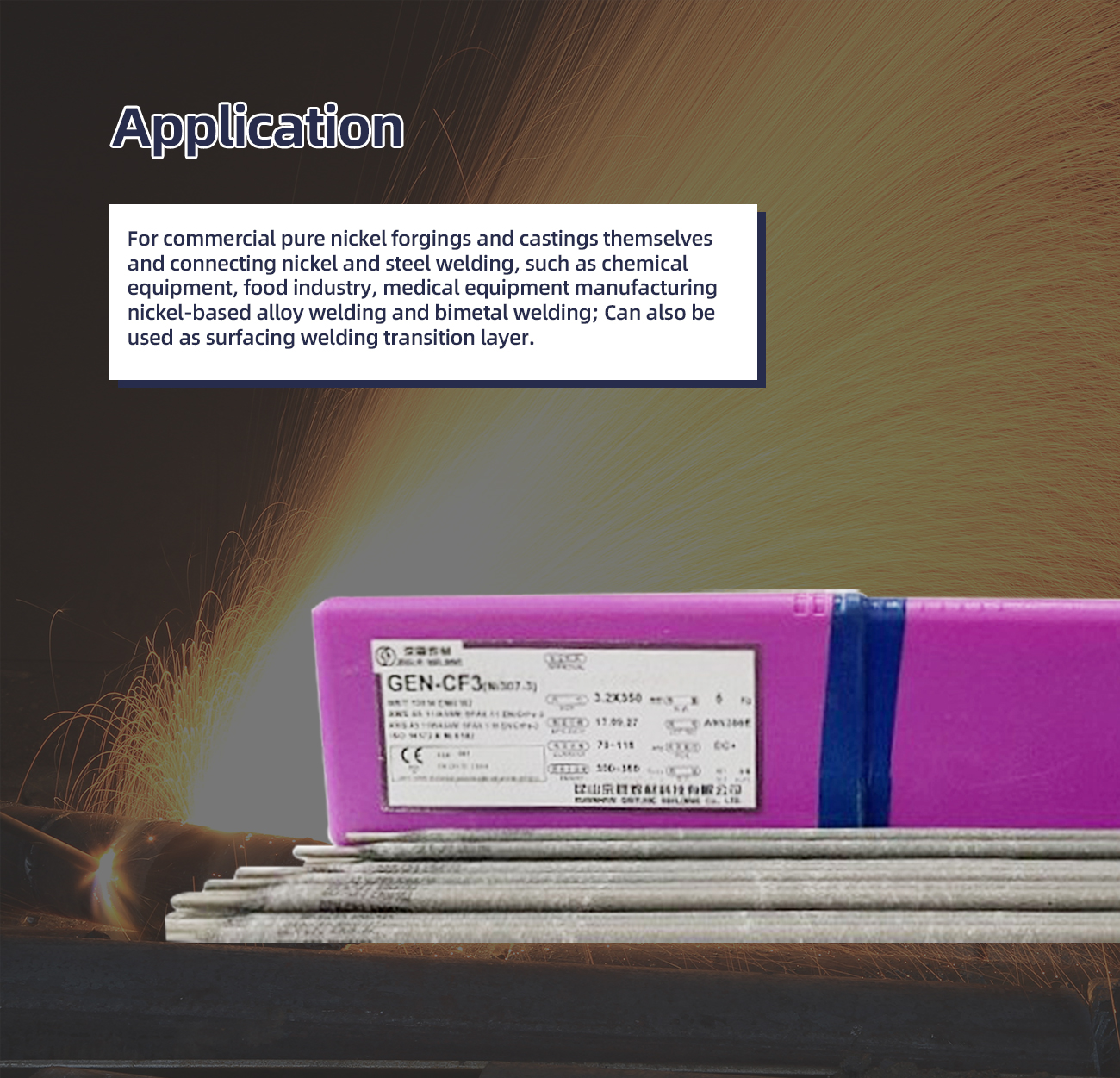

Ny metaly fused dia manana toetra mekanika tsara, fanoherana ny hafanana, ny fanoherana ny harafesina, ny fusion ary ny fanoherana ny crack.

Cr-Mo vy andian-dahatsoratra welding fitaovana sy ny electrode surfacing welding fitaovana dia be mpampiasa amin'ny fitaovana fanadiovana solika.

-

158.000 taonina Suez tanker

Supercore SG

COMPONET CHEMIKA:

| FITIAVANA (wt%) | C | Mn | Si | Ni | Fe | Ti | Cu | P | S |

| GB/T RATSY | 0.10 | 0.75 | 1.20 | ≥92 | 0.70 | 1.0-4.0 | 0.20 | 0.02 | 0.015 |

| AWS RULES | 0.10 | 0.75 | 1.25 | ≥92 | 0.75 | 1.0-4.0 | 0.25 | 0.03 | 0.02 |

| VALUE OHATRA | 0.046 | 0.06 | 0.82 | 95.5 | 0.12 | 2.7 | 0.01 | 0.007 | 0.001 |

FANANANA MEKANIKA:

| NY FANANANA | HERINANDRO (MPa) | HERIN'NY FANITATRA (MPa) | IMPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RATSY | 200 | 410 | - | 18 | ||||

| AWS RULES | - | 410 | - | 20 | ||||

| VALUE OHATRA | 310 | 435 | - | 29 | ||||

PARAMETER WELD RECOMMENDED:

| SPECIFICATIONS DIAMETERS (mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||||

| HERINATRATRA (Amp) | H/W | 65-95 | 70-115 | 95-145 | ||||||

Soraty eto ny hafatrao ary alefaso aminay